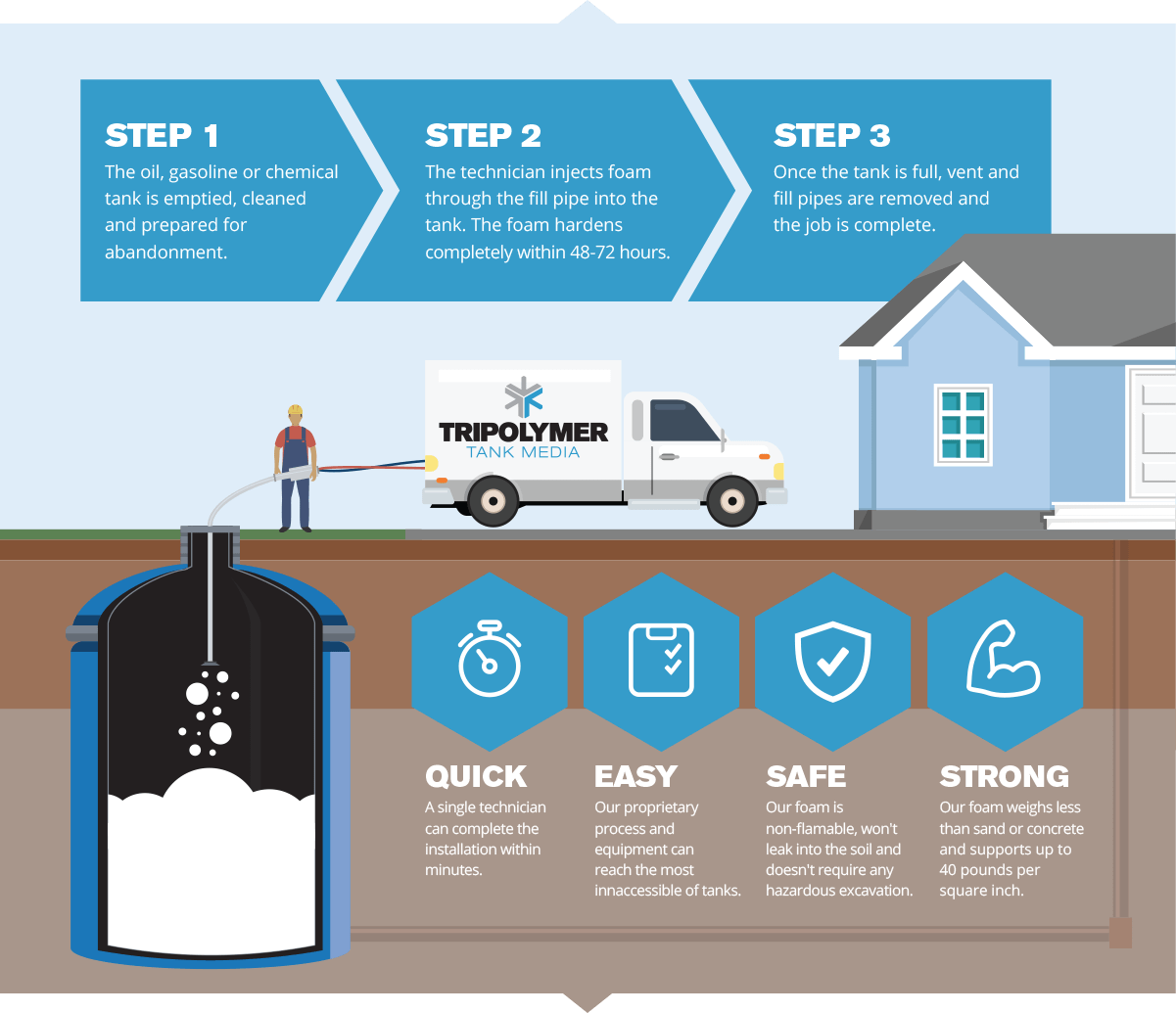

HOW IT WORKS

WHY CHOOSE TRIPOLYMER FOAM INSULATION?

OUR FOAM CAN REACH THE MOST INACCESSIBLE OF AREAS.

While other filling options require a big team and space to park a cement or dump truck nearby, our foam is delivered with a thin hose that is long enough to reach tanks under the foundation of a building. Our technicians can reach even the most inaccessible tanks with little disruption to the property.

TRIPOLYMER TANK MEDIA IS INERT.

The foam is non-toxic, does not use, contain or emit CFC’s, and is safe for the environment. It is non-flammable and will not settle over time.

APPLICATION IS QUICK.

Our foam is administered more quickly and efficiently than the sand or cement slurry filling options.

IT’S LIGHTWEIGHT AND STRONG.

The hardened foam supports up to 40 pounds per square inch, but weighs less than other filling options, so if the tank has to be removed in the future, it will be easier than if it is filled with sand or cement.

IT IS NOT POLYURETHANE FOAM.

Tripolymer Tank Media is a methylene-linked synthetic polymer and is a unique, stable, and safe foam alternative! No petro chemicals are used in the manufacturing of Tripolymer 105-TM (fireguard) foam. Our foam has been used for over 45 years as a permanent, inert, environmentally safe oil tank abandonment media.

TRIPOLYMER TANK MEDIA WAS MADE TO FILL UNDERGROUND TANKS.

Our materials and the equipment used for installation were specifically designed to produce the highest quality foam product for use in underground oil tank abandonment.